Broadcasted live from the land of the potato, Welcome to Words are Winged's Lets Build A Royal 5!

Where the pictures may not matter, and the process is made up!

Picking up after the last segment, you should have the main carriage shift rod in place. Now, what you'll do is unscrew the two small screws on the top left and right of the frame bar that normally holds the segment. These screws, if you look below the bar, jut out, and are used to stop the upward motion of shifting. Once out of the way, you will want to unscrew the activator piece of the ribbon vibrator, and take the small hook on the left side of the rail frame off. You should now be able to drop the escapement assembly into place, with a bit of gentle nudging here and there. Once in place, you'll place the locking bolts into position on each side. They are located...

Here, just past the hex nut/screw. This one is already in. You will then proceed to lock the bolts in place with their respective screws.

Now, we screw in the bottom of the assembly to the arms we added last session. Note that due to the design, you may have to turn the arms hex nut a bit to get everything to work smoothly; the hole in said nut is not centered so as to allow tuning of the position of the arm.

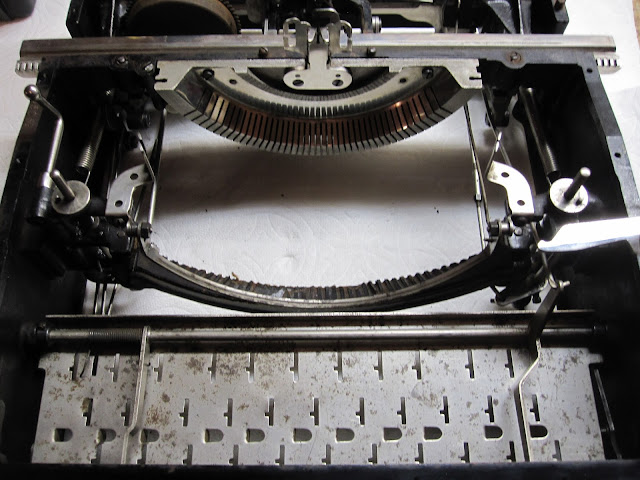

With the machine on its back, you should see this. Once you re-tighten the screws and add the hook back on, you should also make sure that the carriage rail slides smoothly up and down. If it does not, you'll need to adjust those hex nuts.

It took me a few minutes to figure out what the L shaped part was for, but I deduced its purpose; it is part of the backspace. Youll need it, the small screw, and the linkage. The key wont be put in until far later.

Here it is in position, and linkaged up. It connects to the awkward thing from last post.

Now we go ahead and add the keylever guideplateamagig.

I screwd in the front right and the back left screws, and waited to do the other two.

I'm not sure yet what this does, but I do know where it goes. It goes on the back right screw of the guideplateamagig.

Bam. Washer between it and the guideplateamagig, spring attached to small protrusion.

At this point, if your like me, you have had just about enough of that damnable ribbon holder swinging around like it owns the joint. Thus, we add the segment. It has two emplaced rods to ensure perfect alignment. Gently push it place, then tighten the screws to perfection. Watch to make sure you get the ribbon vibrator on correctly.

Just because I could, I threw on the shifting springs for the sake of it. Watch to make sure the left side is symetrical to the right; there is another catch on the shift rod that is meant for a linkage down the road.

Now we throw on the front shift bar. It has a spring on it that will press against the front of the frame, and force the rod into its rest position. I think I turned the spring twice to give it proper pressure. To place this, unscrew one side from the frame, set the rod onto the in-place screw, then reattach the other screw.

Now, the linkages for that rod. You will need to unscrew the backspace part again, as well as the hook from last session. The smaller linkage shown below attaches the shift rod to the hook, and the larger one fits onto the previously mentioned position on the super-rod. Replace the backspace part and the hook, making sure that it clamps onto the rail frame when at rest. If not, adjust the hexnut on it, or lengthen the linkage.

Now add the first step plate. You may have to loosen the guideplateamagig to allow it to slide into position. Take care to get the guideplateamagig back into its proper position afterwards, however.

Now for the spacebar. Again, I turned the spring twice I beleive. Slide one side into the proper hole, having loosened the washer, then jimmy it so that the other end slips into its position. Having kept at least one sides washer in its original spot, youll have no issues with where the spacebar should be resting. Tighten the other washer after you move it back into place, and you should have the following.

A spacebar reaching for the stars.

Throw its linkage into place (it connects directly to the universal bar, you'll see the spot) and test that it activates the escapement when you press it. Adjust the linkage by slightly bending it if necessary.

And finally for Part 2, we add the second cover plate, which will hold the spacebar down. Your Royal 5 is starting to come together!

Next: Assembling the main systems (Part 3)