No, not THAT kind of "going postal". Rather, the kind involving our beloved mechanical devices.

They say good things come in two's, right? Or is it fours?... Maybe 3/8ths?

The Postal has been on my "Wanted" list for quite some time, but when they turn up for sale they are usually 1) in good condition and thus 2) far beyond my price range. These two rust buckets were closer to my range of affordability, so I jumped at them.

I believe the one on the right is a 3, and the one on the left is a 5.

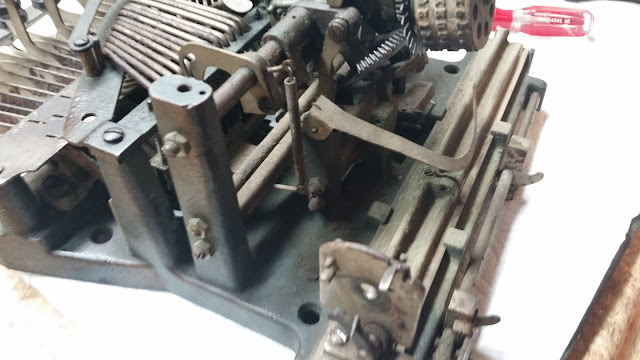

First things first, I had to do what I had to do; I tore the Postal 3 to pieces, learning much about its function along the way.

The prognosis is thus far good. Once I get a few stuck screws out, I can work on cleaning the whole thing up, with a new layer of shiny black paint (hurrah, no decals to worry about).

The Postal is, in base terms, like someone literally took a Blickensderfer and a Hammond, blew them up, mixed the debris together, superglued the parts back together willy-nilly to make a functioning machine, and baked at 425 degrees for 18 to 20 minutes.

Here's hoping that I can get it functioning decently. I really, really want to see if its a better machine than a Blick in terms of usage.

Despite the gap in blogposts, my workshop has not been sitting idle. I was able to get a rust bucket American No. 8 back up and running, and despite the simplicity behind the mechanics, these things do not type very well. I'm sure brand new they were decent, or if kept in good condition all this time still do ok, but this rust bucket in particular really shows the damage it took sitting in a Maine barn for 50 years.

I also was able to finally get a Molle from a fellow collector. These things are really cool, and seem to be very decent typers when in a maintained condition. The keyboard spacing, due to the design, renders it hard for me to accurately type much on it though. The top rows are ok, but the bottom row is so far off I type one character off almost all the time.

That's it for the typewriters for now. I've recently been trying my hand at other odds and ends, and one of those odds is an art-deco themed wooden notebook. The three rings can be opened, so new paper can always be put in.

A letterholder was crafted as well.

A clock, too. I'm working on making a mechanical clock out of wood, but making wooden gears by hand takes quite a bit of time. Probably need some better tools.

And a friend requested a clipboard.

That's it for the non-typewriter stuff.

By the way, shout out to anyone from Maine for your Senator Angus King. I have CSPAN on in the background today, and he gave a very good speech in regards to the deficit today as the Senate works on that new tax reform bill.