A note first about Oliver's before we begin this shorter entry.

Oliver's, without oil, are like automobiles without petroleum. They will simply refuse to work correctly. Thus it is important to oil those parts that move, not too much not too little, and work the parts so that the oil gets into the seams it needs to be in. This is especially true after cleaning a machine as I have presented here. Of notice is the carriage assembly pivot points. Without oil, shifting will be sluggish and improper. After oiling, it will be found that shifting will spring with life, joyous to allow you to print capitals or figures. Anyway, here we are: Do you want to build an Oliver, part 4.

First up on the list is the shifting superrod. There are ball bearings on each side, 5 per side, that allow a smooth shifting experience. I prefer the Oliver 5's method, which is simply a hollowed cone-shaped end which a cone shaped screw fits in. Ball bearings here seem rather unnecessary. But here they are. So try your best to get them in their positions and gently place the bar into position, and tighten the screws.

The middle of the bar has a large jut upwards which connects to the carriage/escapement assembly. Attached point A to point B via spring plate already in position.

Now we add the space-bar assembly.

It screws into the large plate we added in the previous part. Make sure the holes align at the top of the picture so that the space-bar itself can readily be placed into position. Also make sure the hooked bit is in its place before completely screwing anything down, and ensure it is relatively firmly held against the space-bar lever.

Before we add the spacebar, we add the small decorative plate which goes right below it.

Shiny!

Now the space bar.

The underside of the machine is a bit cramped by this point, so with patience screw the nuts onto the end of the space-bar poles and ensure a firm tight connection.

Your keyboard is complete!

Now we add the piece which ensures the space-bar doesn't descend too far.

Here it is in place. Make sure it is far enough towards the back of the machine to not inhibit the space-bars normal operation.

Ta-Da! The underside of a (for the most part) completed machine! The only things missing are the left margin lever, which I add almost last of all things for some reason, and an odd subsystem which I have no clue what it does. Ill get to that in the final part of this How To.

However, this machine is ready to type! I grab the carriage from my Oliver 5 (Don't mind the horrid paint-job please), some paper, and a ribbon.

Olivers need their special sized wooden cores. Normal spools wont work on them, so I grab my Oliver 5 spools as well and throw the ribbon on them.

Throw the carriage on, roll some paper in, and prepare to see beautifull and perfect typing! :D

Or the chaotic mess which can be easily expected after taking a machine completely apart. After a few moments of typing, I realized that my left side keys were set improperly in comparison to the right side keys, or vise versa. To change this...

We mess with these two scews. The left, larger one locks the piece in position, and the right, smaller one actually raises or lowers the entire tower, thus tilting the type left or right.

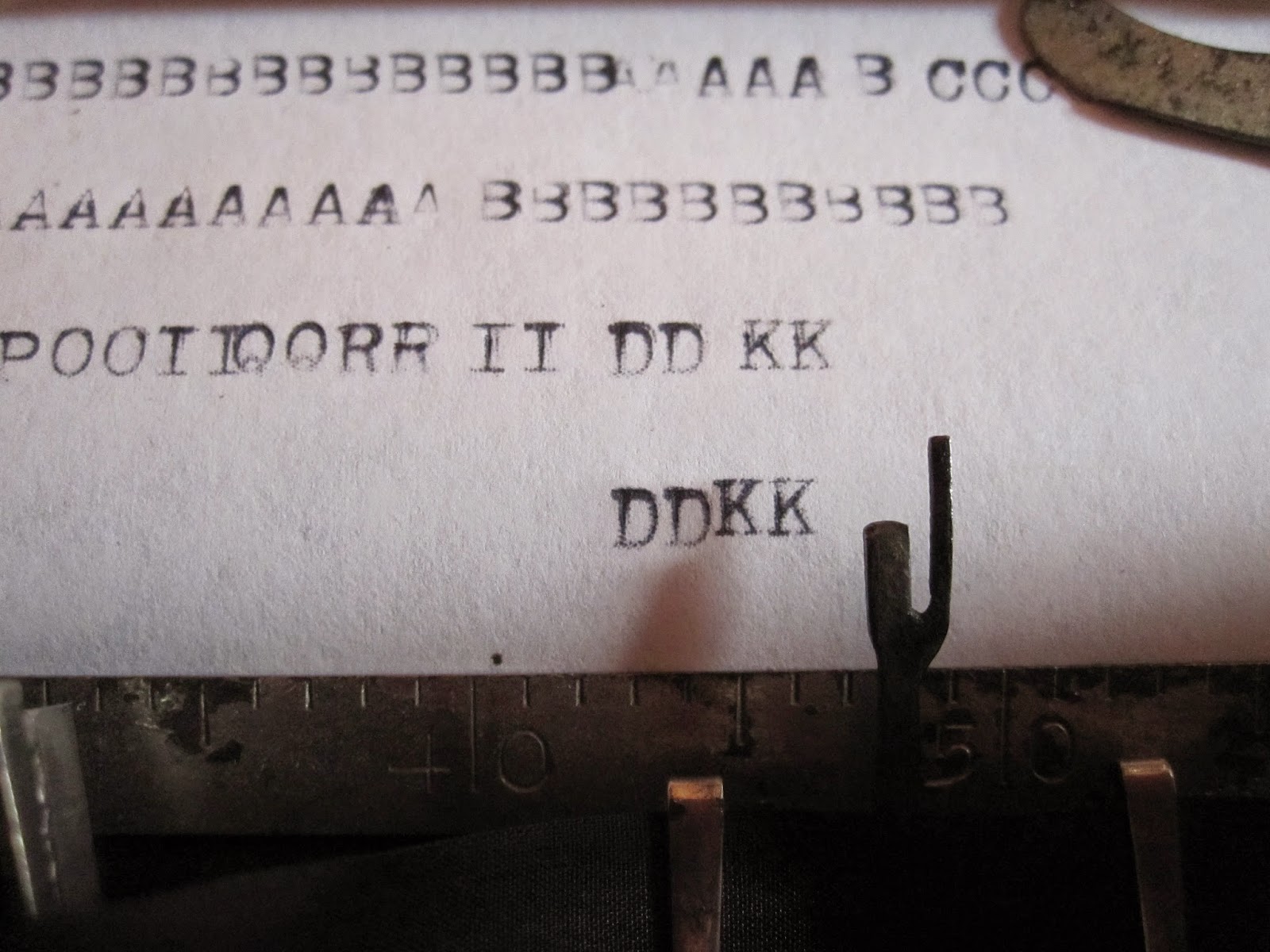

I was able to close the gap between DD and KK, and (not pictured) made the space just a bit more between the two, bringing the two towers (after a few adjustments on the left tower as well) into position and ready to conquer middle earth.

Its got impression issues as well, but by golly I was able to somewhat type that most famous line. Im talking about baabABBBAA, of course.

The carriage is just as important to the adjustment as other things. Changes must sometimes be made to this bit shown here, which rides the back rail. Raise or lower to your desire.

This means, however, that I need the Olivers original carriage to properly tune it further, so I finish off what I have on hand ready for the body, the patant plates, and prepare to dissassemble the carriage for cleaning.

Up next: Do you want to build an Oliver? Part 5; The Finale

Where we show how to build the carriage, make tuning adjustments to set the whole machine into alignment, finally place the left margin release which should have been done sooner, make a few final additions to the machine, and bask in the glory of an Oliver 11 brought to life once more. Stay tuned!

Bravo!! What you have done so far is beyond amazing. I look forward to the finale and the final adjustments that you will make.

ReplyDeleteThat's a good tidbit of information about the adjustment screws that raise and lower the towers.

I typed a letter on my newly functional Oliver this morning - the typebars are very bent so it looked rather wacky.

I'm glad to provide information of use. This series is not so much designed to actually show someone how one should build an Oliver as much as its meant to help someone stuck in a situation where they forgot where something went, what it did, and about when it should have been placed back in to the machine.

DeleteAnd Olivers are noted as possibly having wacky typing if they've been beaten up, as yours must have been if it hit its right tower as hard as you describe.